Brake system engineering is very crucial as it ensures the overall safety of the vehicles. Brakes must perform efficiently as vehicles become powerful & also going driver less in some countries, in such scenarios safety relies completely on the emergency braking systems. Thus, the vehicle manufacturers need to take utmost precautions to meet safety standards & performance while designing the brake systems. Braking systems should be easy to handle & comfortable to press without any hiccups even during an emergency. All of this, with costs that can be an edge over the competitors.

There are many challenges involved in designing of these brake systems, such as life span calculation of components, minimising wear and tear, selecting the right component for longer life of the brake systems, calculation of impact on performance if and when any component wears out.

Overheating and thermal deformation of disc brake systems during emergency braking are becoming critical issues. To design the brake systems, precise prediction of the maximum temperature is needed, especially for discs and linings. The brake manufacturers are using different methods to test new coatings, increase in cooling efficiency, along with reducing time & cost of physical hardware testing. At a component level, some common tests for a disc brake assembly include

- Durability analysis of caliper bracket & housing – The caliper bracket is critical as it takes frictional forces during braking. The caliper bracket should not yield or overly deflect during braking. The objective is to determine stress and deformation due to braking and this typically includes analysing thermal effects due to friction-induced heat.

- Caliper seal analysis – Done to analyse piston retraction behaviour. Caliper seal, besides preventing leakage of brake fluid, also retracts caliper piston after braking. Piston retraction depends on the profile of the rubber seal and the groove

- Contact pressure distribution (disc and pad) during brake application – Detailed analysis can provide more accurate insights into brake performance with respect to stress distribution after assembly. This is done by bolt pretension and interference fit resolution & establishing contact between pad(s) and stationary disc followed by establishing steady state rotational motion

Simulation tools helps in addressing these and many more challenges & also reduces the costs & time associated with physical tests. By using simulation tools, one can check working of brakes in wet & slippery conditions. It can help predict failure of components ultimately predicting the life span & performance & durability of the brake systems. It can also help minimise noise & vibration of brakes, everything in real time where the cross functional teams can review & suggest changes as needed.

Simulation for Brake Systems Development:

SIMULIA from Dassault Systemes offers different solutions which conduct fatigue & durability analysis for the brake systems (Fe-safe), optimize the process (Tosca, Isight) & study Multiphysics in strong purpose reliability tool Abaqus.

Fatigue life estimation can be calculated by analysing stress distribution, especially hotspots (regions of high stress concentration) which affect the durability of the caliper, deformation, to be compared with some benchmark value for compliance. Friction-induced heat leads to brake fade (reduced stopping performance). Along with wear, this may lead to noise and vibration issues.

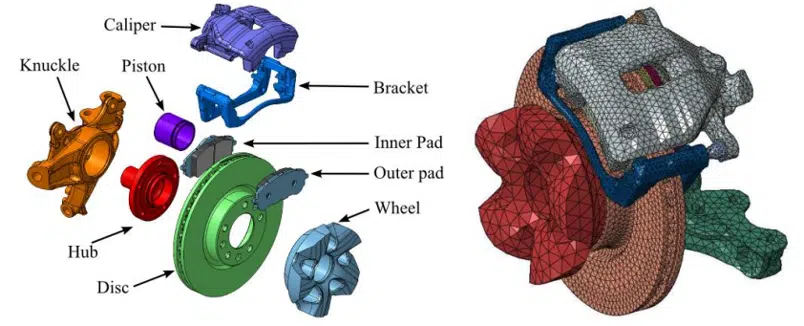

A fully-coupled thermomechanical analysis is required for accuracy. Friction induces heat, which may affect parameters such as friction coefficient, gap conductance (across contacting surfaces), and material properties. A detailed finite element model of the brake assembly for thermal simulation, with a cross-section to show details can be developed using our simulation tools.

We can achieve more using the simulation tools –

- Improved structural integrity Shape Optimization – Any design proposal from topology optimization should usually be “finetuned” to reduce stress hotspots – this improves structural integrity (performance and life). Shape optimization from Tosca is a powerful technique to achieve this.

- Insured reliability Durability Analysis for fatigue life estimation – Usually, components are designed for a target fatigue life based on standard usage. Fe-safe provides advanced fatigue algorithms to calculate fatigue life accurately, it also comes with a built-in material database with fatigue parameters.

- Conceptual lightweight design Topology Optimization – Tosca provides powerful topology optimization technique to obtain a lightweight yet stiff design through optimal distribution of material on the disc.

- Understand physical behaviour Structural & Thermal Analysis – Frictional heat generated during a braking event is conducted through both discs and linings and cooled by the air around them. Abaqus/CAE is used for complete finite element modelling of the brake assembly. Analysis of seal groove geometry requires accurate material and contact modelling. Abaqus provides hyper elastic material models and contact algorithms for such challenging nonlinear problems.

- Exploration of design alternatives Parametric Optimization – Using Isight, a parametric optimization can be performed to maximize cooling

- Shape optimization – Tosca can be used with fe-safe to fine-tune the design for better fatigue life and factor of safety.

Simulation is the future of brake systems development! Are you ready for the transformation?

About Vias3D:

Vias3D engineering and simulation team combines decades of analytical and design experience. They have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modelling techniques such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG) and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.