Abaqus/CAE is a versatile nonlinear FEA software, that is used in various industries to perform…

VIAS3DMarch 6, 2023

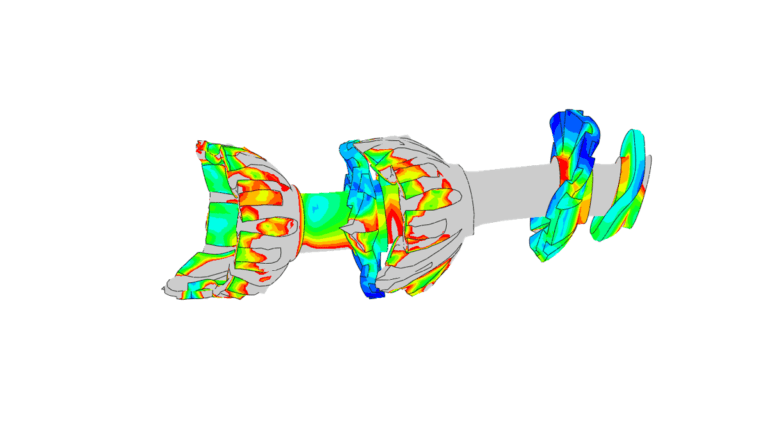

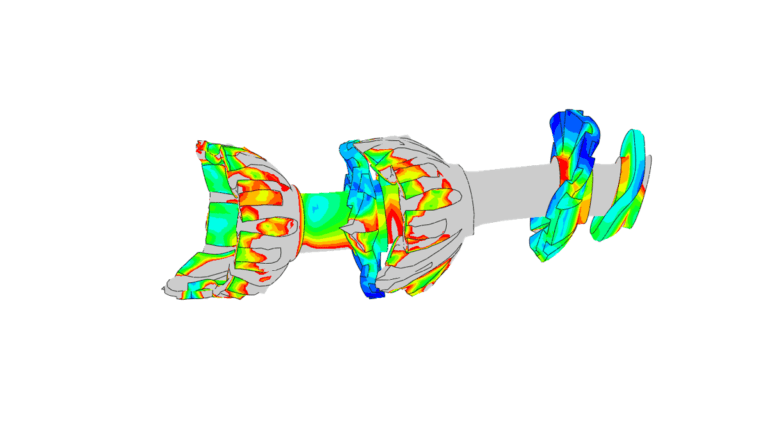

Heavy repetitive loads and long operational hours makes the equipment from the energy sector extremely vulnerable to wear and fatigue failure. In VIAS3D, over the years, we have provided solutions for detailed structural and fluid dynamics problems for multi-disciplined frameworks in the energy and materials industry. These solutions encompass efficiency improvement, design optimization, contact stress analysis, coupled single and multiphase flow analysis of conventional and non-conventional energy producing equipment and advanced electromagnetic analysis for performance optimization.

Related Blogs