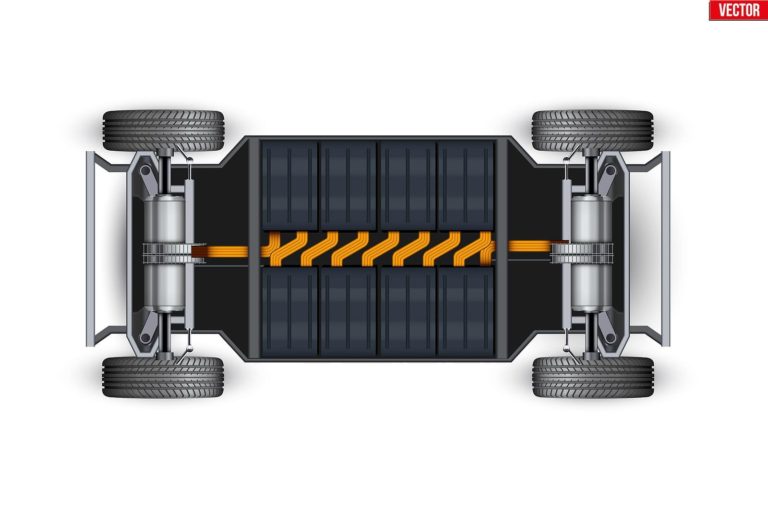

Lithium-ion batteries are the best rechargeable batteries available today as a power source in electric vehicles due to higher energy density, voltage capacity. But there are challenges in Li-ion as it is quite sensitive to heat and requires a protection circuit to maintain safe operation. Abusive usage of these batteries can lead to a catastrophic failure called thermal runaway (TR) – a fast, violent, self-accelerating exothermic chemical reaction releasing very large amounts of energy accompanied with rising temperature, pressure and in some scenarios release of toxic gases through venting.

These released toxic gases are flammable and the high temperatures of the battery can ignite them leading to a fire hazard. Thermal runaway can be caused by overcharging, over-discharging, overheating, internal cell short circuiting, and cell structural damage due to crash and other abusive usage.

Simulation tools from SIMULIA brand of Dassault Systèmes such as Abaqus, Isight, Tosca, fesafe etc. are being used by the major battery manufactures and Electric Vehicle OEMs for ensuring battery strength, stiffness, safety, and avoidance of thermal runaway.

SIMULIA provides multi-scale, multi-physics approach for realistic battery performance simulation. Multi-scale multi-physics allows to model electrical, chemical, thermal, mechanical behaviors of battery at electrode, cell, module, and system level. Some of the important and necessary battery simulations using SIMULIA.

- Battery cell crush analysis

- Short circuit analysis

- Thermal runaway analysis

- Heat transfer (cooling) analysis of battery module

- Drop/impact analysis

- Electromagnetic analysis

Benefits of Battery Simulation

- Accelerate the development of battery systems

- Boost the structural integrity validation of battery cells and packs

- Optimize the safety and thermal behavior of battery cells, packs and systems

About VIAS:

VIAS, in partnership with Dassault Systemes, can be your facilitator in this transformation process – be it consultancy, sales and support or training – we have it all. With a dedicated team of Doctorates and master’s having strong expertise in Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG), data analytics and domain knowledge of various engineering streams, we can handle simple to complex workflows. We have strong expertise in dealing with both mitigation and life extension achieved by following the procedures given for fitness-for-service (FFS) in ASME FFS-1/API-579 within an integrity or risk reliability management framework.

Contributed by:

Raghavendra Banchhor

[email protected]